ZERO - EMISSIONS OFFSHORE WIND O & M OPERATIONS

How did ER-MARINE start in 2021?

FLOATING WIND AND HYDROGEN – THE PERFECT MATCH

Our concept aims to produce green hydrogen using renewable energy from offshore wind to use the hydrogen, ammonia, as energy carrier on board the vessels involved in the offshore wind farm O&M operations. Making this a true zero- emissions operation.

Where are we in 2024?

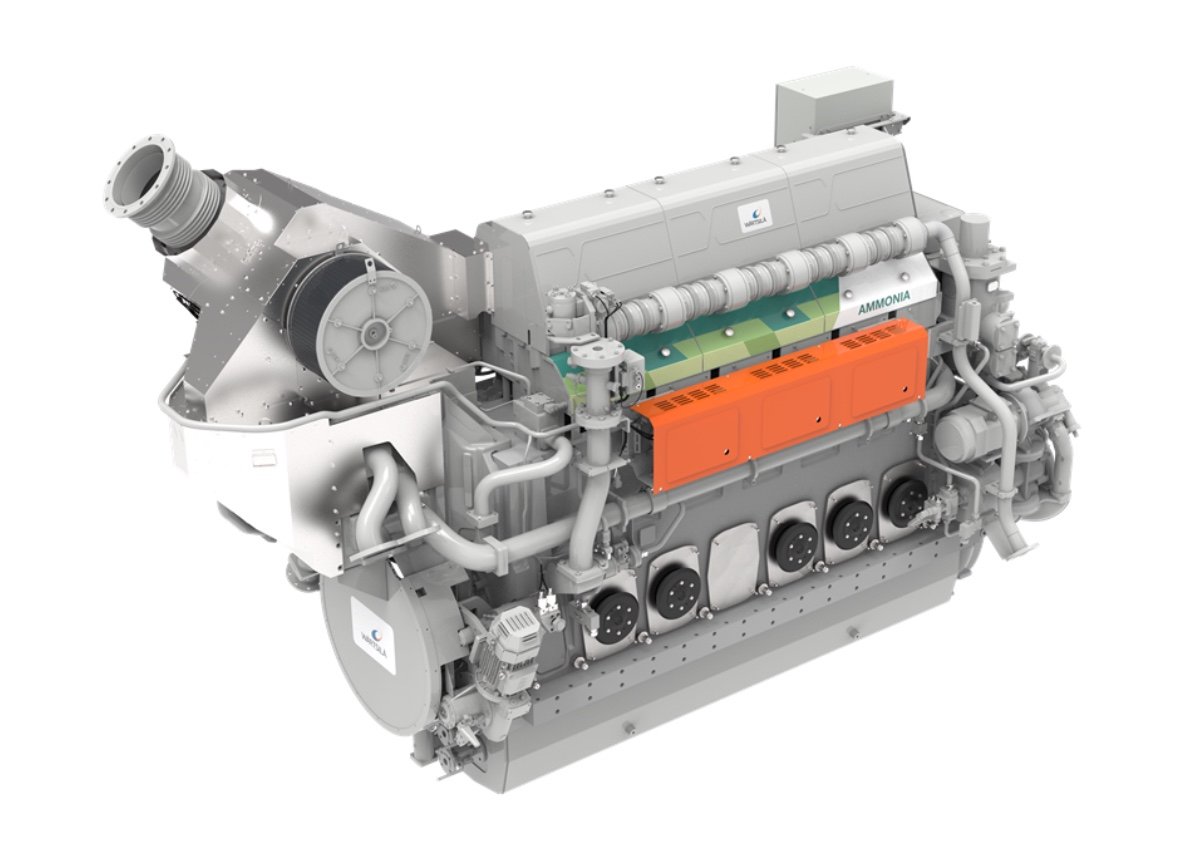

With recent developments where ammonia can be used in DF (Dual Fuel) solutions, this opens up new opportunities for marine applications.

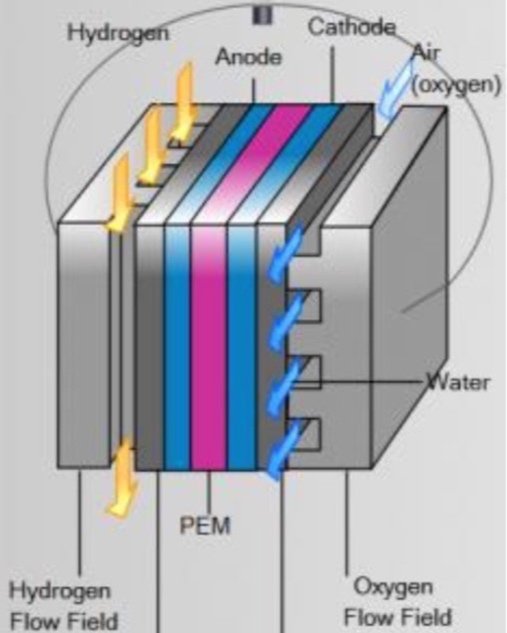

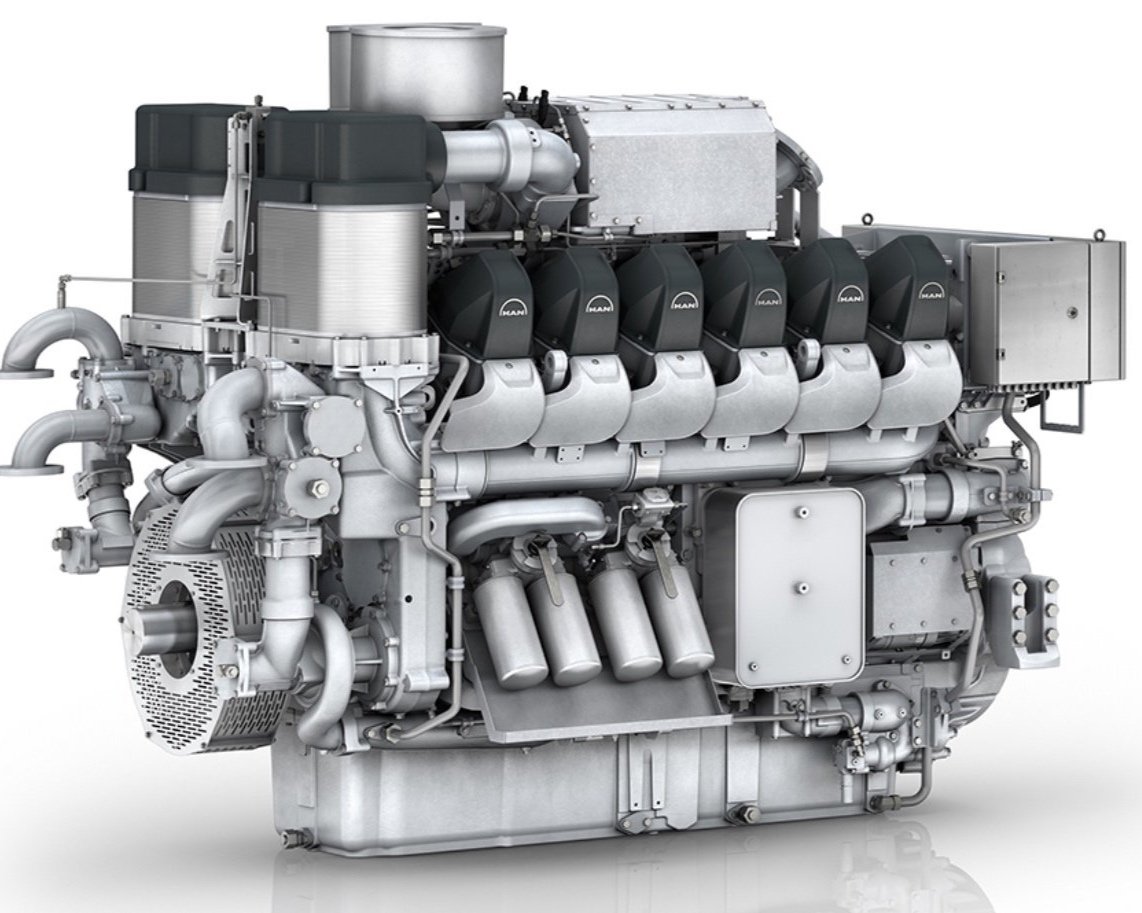

The 4 stroke DF (Dual Fuel) engines able to run on methanol or ammonia become commercially available. This allows us to develop zero- emissions solutions either with fuel cells or internal combustion engines or a combination of both.

Where are we heading for in 2024?

ER-MARINE focus on developing the marine zero- emission concept, targeting the vessel segment used in offshore wind O&M.

Our bold ambition is to co- develop a zero- emission solution for a CTV (Crew Transfer Vessel) for future offshore operations in South Korea.

Erik Roelans has first-hand experience with SCR applications installed on board drillships dating back to 2009–2011, when SCR’s were installed during the newbuilding process at the South Korean yard. During the commissioning of the power plant, we encountered issues with ammonia slip exceeding design criteria, especially during very fast load changes on the engines. It was a demanding task to balance NOx and N2O emissions throughout the full load spectrum of the engine. This was a steep learning process with very valuable lessons learned in respect to ammonia slip back in 2008–2011.

A few advantages and disadvantages of ammonia as a marine fuel

Ammonia as fuel has the advantage that it releases no CO2 when combusted, it is carbon- free when produced from renewable energy and is relatively easy to store and handle on board the vessel.

A few of the disadvantages of ammonia :

Slow to ignite and burn in an engine (it requires a small amount of pilot fuel to ignite)

Highly toxic, suffocating and corrosive

Low volumetric efficiency and energy density (it requires bigger fuel storage on board, about 3 - 4 times more than MGO)

NOx emissions to be handled with abatement systems (SCR technology)

Risk of ammonia slip (N2O) during combustion

CO2 to be used to extinguish ammonia fires (water can react with ammonia and forms toxic gas)

Regulatory frameworks for development of ammonia as marine fuel are still being developed

Especially the risk of ammonia slip during combustion is a serious concern.

In theory, burning ammonia yield only harmless nitrogen gas (N2) and water as products. In practice, ammonia combustion can release harmful NOx and N2O pollutants. Especially during fast load changes or if the hot combustion gases imping upon cold cylinder walls, N2O emissions can quickly accumulate.

Researchers found that if ammonia fuel achieves a market penetration equal to around 5% of the current global primary energy demand (which would require 1,6 billion tons of ammonia production, or ten times current production levels), and if 1% of the nitrogen in that ammonia is lost as N2O, then ammonia combustion could produce GHG emissions equivalent to 15% of today’s emissions from fossil fuels. The GHG intensity of such a loss rate would mean that burning ammonia fuel would be more polluting than coal. Ref. Michael E. Mueller, associate chair and professor of mechanical and aerospace engineering